The scientists have long been working on concept of converting common body movement into usable energy. The idea is simple if the human body is in constant motion, walking, breathing or even the soft rhythm of heartbeat, why not tap into that motion and turn it into electricity? A research team from the Centre for Nano and Soft Matter Sciences (CeNS), Bengaluru, has taken a move forward toward making this future a reality. Their newly developed flexible piezoelectric device demonstrates how small mechanical actions can generate clean and continuous power by opening possibilities for advanced wearable health technologies.

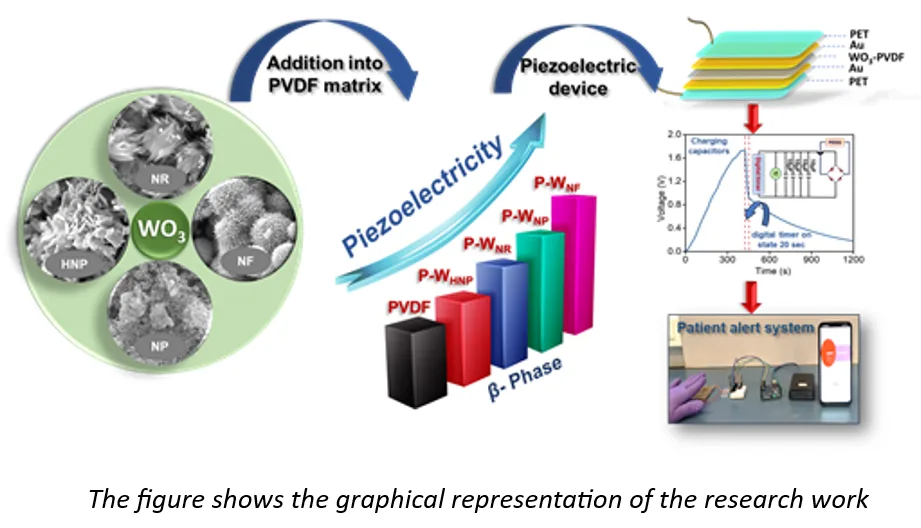

At the core of this development there is a thoughtful design approach based on two integral materials, first is a unique nanostructure of tungsten trioxide (WO₃) and another is flexible polymer called PVDF. Although PVDF is already recognized for its ability to convert pressure into electricity, the CeNS team wanted to push it further.

Tracing the right nanostructure

The researchers decided not to just experiment with one type of WO₃ nanomaterial but to explore how its shape, structure and surface behaviour change the final output of the device. They tested four different morphologies of WO₃, each with its own physical characteristics. Among them one have a flower-shaped nanostructure.

What made this “nanoflower” special was its crystal arrangement and its surface charge. It had three unequal crystal axes and exhibited the highest surface charge of all samples measured as a zeta potential of −58.4 mV. This strong surface charge allowed it to bind more effectively within the PVDF matrix, thus enabling the polymer to form a higher proportion of its piezoelectric phase. This flower-shaped nanomaterial interacted with PVDF in a way that it can maximize the electrical output, when the material was pressed or bent.

The researchers then carefully optimized how much of this nanoflower should be mixed into the PVDF too little would not make a difference, too much would weaken the material. After testing several combinations, scientists found an ideal concentration that yielded the strongest performance.

Building a self-powered device

With the optimized nanocomposite material, the team built a prototype device capable of harvesting energy from mechanical motions. The device is flexible, thin and lightweight constructed with important qualities for wearables. It could easily be bent, pressed or stretched. Each of these mechanical actions resulted in the creation of electrical signals, proving that the combining of PVDF with nanoflowers was not only theoretically effective but also practically so. Fabrication and testing verified that this device was indeed capable of real-time energy generation with no need for an external power source.

This is a crucial achievement in self-powered electronics. The majority of wearable health gadgets today runs with batteries, which often require frequent recharging or replacement. A self-powered system can continuously function by drawing energy from the movements of the wearer. This improves convenience but also allows for continued monitoring, which is especially desirable for those who rely on having their health consistently tracked.

Smarter and lighter healthcare tools

Early tests carried out by the CeNS team demonstrates great promise for this device in biomedical applications. Being highly sensitive, it can detect signals from a wide range of movements of the human body from subtle motions of pulse/heartbeat to much stronger movements of gait or breathing. This makes it suitable for both wearable health monitoring bands, garments as well as patches. In these systems, mechanical activity is naturally available all day long, thus the device could convert these motions continuously into useful electrical signals.

What really gives this innovation, is its particular significance of the potential to hold it for use in medical monitoring. In most medical facilities and home care settings, the monitoring of vital signs relies on equipment that needs to be plugged into an external power source. This could make a self-powered sensor much more seamless, lightweight and independent. Patients might wear a small patch that would monitor heart rhythm or breathing patterns and the sensor would power itself from the movements of the body.

The findings was published in ACS Applied Electronic Materials. The systematic approach, studying how different nanostructures behave within a flexible polymer, also helps scientists understand how to design the next generation of piezoelectric materials. This work demonstrates that the appropriate type of nanofiller is linked with enhancing energy conversion efficiency.

A step toward future energy-harvesting fabrics

As wearable electronics become more prevalent, the demand for comfortable, small and self-sustaining devices is rapidly increasing. The CeNS innovation points to that future. Such nanocomposite-based devices could be sewn into clothing, shoes or even everyday accessories.

Imagine a fabric that produces electricity through movement or shoes that charge small sensors solely with your steps. Smart textiles with the feel of a normal garment yet harboring intelligent sensing layers are no longer farfetched dreams. It is with such devices, as this one presented by the CeNS team ideas like these come a step closer to reality.

The investigation was conducted by Mr. Ankur Verma, Ms. Pritha Dutta, Mr. Nilay Awasthi, Dr. Ashutosh K. Singh and Dr. C. K. Subash. The team collective effort forms a foundation for smarter, more efficient and more sustainable healthcare tools. The work also strengthens India’s growing presence in advanced material research and wearable technology development.

Their teams vision goes beyond this prototype toward a future in which such nanocomposite devices will play a key role in next-generation biomedical wearables that contribute to more responsive and personalized healthcare systems. Moving society toward compact and intelligent devices, innovations like these are bound to reshape the way health will be monitored and managed.

The flower shaped WO₃, PVDF piezoelectric device developed at CeNS exemplifies how material science has direct relevance in shaping the future of healthcare and technology wearables. Focused on getting the right combination of structure, charge and concentration, the scientists have fabricated a flexible device capable of converting energy from basic everyday movements.

Its sensitivity, efficiency and versatility make it well suited for medical monitoring and next generation wearable systems. This demonstrates that with thoughtful material design, self-powered healthcare devices are not just an idea but a tangible reality.

Publication details: DOI: https://doi.org/10.1021/acsaelm.5c00962

Comments