The sooner we recognise that delays and sub-optimal infrastructure is costing us money, the better. We need to bridge this fundamental gap in our capability to provide better infrastructure. Our response to emergencies will be enhanced

The build-up along the LAC combined with severe floods in the North and North Eastern States has highlighted the major gap in emergency bridging capability in the country.

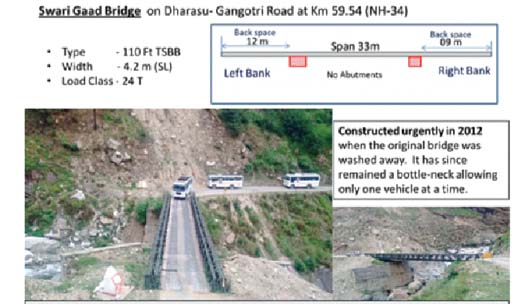

It is a gap which stares at us in multiple situations; most prominently it shows during disasters, year after year; next in speeding up our efforts to replace weak bridges to utilise NHs to full capacity; and most important during the recent build-up, when upgrading roads by the BRO and the Army for military use. Over the years this gap has only grown wider, as the numbers of weak bridges have been adding up. Many of these sub-optimal bridges are due to inadequate response during emergencies. As the need for road communications along our borders peak, upgrading weak bridges becomes urgent.

It is an area that has long been neglected. Today as a Nation, we do not have an adequate response to emergency bridging needs. There are solutions which could be adopted for interim relief and other options which are more sustainable in the long term. But we need to understand and accept the problem first. The solution will follow more easily, for it is well within our reach.

Google ‘Collapsed Bailey Bridge Pics’ and the tabs show

the problem afflicts many states, truly National in character

the problem afflicts many states, truly National in character

Why Emergency Bridging Capability?

The need for emergency bridges during disasters is easily understood. Relief must reach quickly. The commercial activity must start with minimum disruption. But more often the only solution is a Bailey Bridge. This adds up to one more weak bridge on the road and remains for years after being launched in an emergency. Such bridges reduce the capacity of the road drastically, for a single lane-bridge on a double lane road, capable of taking loads just about one-fourth of the desired 70 R (wheel trains up to 100 Tons) gives less than 25% of the desired capacity. Even one such weak link defines the capacity of the entire stretch of road. At 25% capacity, it causes congestion, increases cost and the time for transportation. It also inflicts a larger carbon footprint. We take this for granted as we see no better solution.

The floods in Bihar have brought a sharp focus on weak bridges as summarised in an article in India Today. Bihar has the maximum number of weak bridges, with 6700 about to collapse. NHAI has identified 147 weak bridges on NHs that require urgent replacement; Bihar has the lion’s share of 40; even Maharashtra which is, economically more advanced has 14. These weak bridges collapse faster in floods and need emergent replacement in fold prone areas.

The upgrade to using 2G Emergency Bridges is long overdue and needs to be addressed urgently. The first step is to try out what is available off the shelf and use them for the immediate urgent requirements, not just for roads but for the entire range of applications; in emergencies for road and rail bridges; for construction in tight site conditions where road or rail traffic needs to be disrupted to the barest minimum; as temporary structures to take the traffic load while a route is being upgraded and so much more

Further, in cities, many old bridges, some older than 100 years are now weak bridges or bridges with inadequate width or clearance. They also need quick replacement without prolonged delay or closure of traffic. Underutilisation of any road in cities, rural areas or NHs due to weak bridges is a national loss. Upgrading them is urgent.

The recent build-up along the LAC has further highlighted one more emergent requirement. It is of the Army in operations including equipment for the BRO for road construction and road upgrade. Normal road construction by BRO in the hills is slow due to limited attack points, and so gaps must be bridged quickly and equipment pushed forward to speed it up. Modular bridges are used extensively for this. Unfortunately, all they have is obsolete equipment that provides a quick fix but leads to further complications due to being a temporary solution with grossly inadequate specifications. This causes issues of both safety and underutilisation of the roads.

Repeated Failure of Bridges

Off-late the inadequacy of Bailey bridges which we have been used extensively since the II World War has come sharply under focus. Axle loads of vehicles have gone up. People’s aspirations for better roads have also gone up. Many bridges of load class of 18-24 T (the maximum a Bailey Bridge can give beyond 35 m span), have collapsed when a zealous driver has tried to cross with a sand-filled truck. In one case it happened at the same site, twice within four months, bringing down two successive Bailey bridges. A third Bailey Bridge replaced it for want of a better solution and due to the urgency to keep the road open for both commercial traffic and operational use. That it happened on an NH only shows the gravity of the problem. It is something we have learnt to live with.

If you Google ‘Collapsed Bailey Bridge Pictures’, and see the result, you will wonder why we are still using them. Scroll down some more, and you will find videos on the net, of live collapses.

It is un-nerving. We have many of these bridges along our hill roads, unable to replace them in an acceptable time frame.

Now with the urgency of build-up along the LAC, many of these bridges need an upgrade. But how fast we do it depends on what we use. On hill roads, it is normal to use a truss bridge for say a 55m span Class 70 R IRC Loading. This takes at least three months to fabricate and send to the site. Then it takes a month to launch the truss and another two, to cast the deck and finish the bridge. Six months it is if you can work continuously. If it is affected by winter, closing of the passes or heavy rains, you can easily add another six months to it.

What is used in other Armies is the next generation of the Bailey Bridge, let us call it the 2G Emergency Bridge System for this discussion.

These can give you over 60m span, Class 70 R (double lane) and be launched in 2 weeks, even faster, if you work day and night the way the BRO and the Army normally do in emergent situations.

It is time we graduated to using such 2G Emergency Bridges to have better response capability in emergencies. Other Nations have changed to 2G over 30 years ago.

Bridge launced by IC. Launch witnessed by NHAI officials in Feb 2016

Exploring 2G Emergency Bridges

So, what do the 2G bridges have that makes them better. In the first place, they have retained all the advantages of the Bailey of being modular, enabling quick launch in difficult sites with no welding or riveting on the site. Next, they carry much heavier loads, almost 6-8 times. They can take 70 R loading and even SV Classloading (Specialist Vehicle require 200 Ton wheel loads to pass) and with it allow for from 1 to 3 lane traffic. Most important these bridges can be used in emergencies and retained as permanent bridges as they meet all the requirements of permanent bridges.

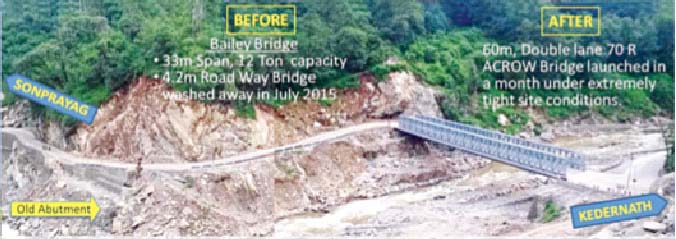

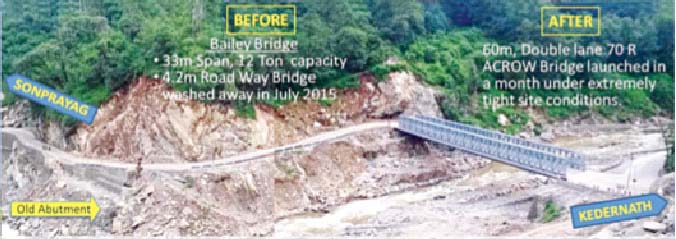

An example of this is the Acrow Bridge launched in Sonprayag en-route to Kedarnath on NH 107. It is a two-way, Class 70 R, spanning 60m. It was by the State Government with World Bank funding, conceptualised by ICT, Green Park, New Delhi, an Infra consultancy firm, which had been employed to design bridges to re-establish connectivity after the initial deluge in 2013. This bridge was launched after a critical Bailey Bridge was washed away in a second flood in Jul 2015. Launched in less than a month in Mar 2016, it enabled the ‘Yatra’ to take place on schedule, raising the morale of the locals and reviving much needed commercial activity in the region.

Such 2G Bridges can be stocked, ready to be moved at short notice to a site. Being modular, they can be designed quickly to suit the site and loading conditions using the same basic structural components and launched with the least disruption to traffic. Such bridges are also available on lease in the US and Europe for a variety of situations. Should a bridge on an NH require an upgrade, this bridge can be launched temporarily, while the regular bridge is being refurbished or rebuilt.

This ensures no disruption of traffic; there is also no need to acquire land permanently for a new bridge.

In many construction sites where access is a problem, leasing these bridges is cost-effective, so that access to the site is eased, and the bridge returned after the project.

The equipment is also used for rail-bridges and shoring in emergencies. It can be put to special uses too, such as movable bridges, a most complex bridge arrangement that can allow shipping traffic to pass by raising the span of the bridge. All this has made the 2G bridge even more versatile than the first-generation Bailey Bridge which, was considered exceptionally versatile for the II World War requirements. Bailey Bridges have been credited with being one of the major reasons the Allies won the II World War.

Even as we learn from available systems, we should plan for the long term, to Make in India. And here we need the forethought to think ahead. Think of 3G if you want to get ahead truly. Look at Bridges which are even quicker to launch, with more options of loading and number of lanes; bridges with enhanced performance along with its entire range of applications and all this, ensuring it is manufactured to world-class standards. This should not be difficult using Indian designers and enterprise. The talent is there. The issue has just not been addressed seriously in the past and will take a little time once we start

The Way Forward-towards 3G Bridges

The upgrade to using 2G Emergency Bridges is long overdue and needs to be addressed urgently. The first step is to try out what is available off the shelf and use them for the immediate urgent requirements, not just for roads but for the entire range of applications; in emergencies for road and rail bridges; for construction in tight site conditions where road or rail traffic needs to be disrupted to the barest minimum; as temporary structures to take the traffic load while a route is being upgraded and so much more.

Even as we learn from available systems, we should plan for the long term, to Make in India. And here we need the forethought to think ahead. Think of 3G if you want to get ahead truly. Look at Bridges which are even quicker to launch, with more options of loading and number of lanes; bridges with enhanced performance along with its entire range of applications and all this, ensuring it is manufactured to world-class standards. This should not be difficult using Indian designers and enterprise. The talent is there. The issue has just not been addressed seriously in the past and will take a little time once we start. But start we must.

No discussion is complete without the cost. By their very use in emergencies, such bridges are always winners. The 2G Bridge in Sonprayag, for example, more than earned its costs in just one season of enhanced commercial activity during the Yatra. The absence of these bridges is leading to accumulated losses with every emergency. We are spending more not having these bridges with bottlenecks on the road and delays in construction, where time is of the essence. The sooner we recognise that delays and sub-optimal infrastructure is costing us money, the better.

We need to bridge this fundamental gap in our capability to provide better infrastructure. Our response to emergencies will be enhanced. Our attitude towards accepting delays will change.

(The writer is former DG Border Roads Organisation)

Comments