In a landmark decision set to reshape India’s technological and economic landscape, the Union Cabinet, chaired by Prime Minister Narendra Modi, has greenlit the establishment of India’s sixth semiconductor manufacturing unit near Jewar airport in Uttar Pradesh’s Yamuna Expressway Industrial Development Authority (YEIDA) area.

This ambitious project, a joint venture between Indian tech giant HCL and global manufacturing titan Foxconn, marks Uttar Pradesh’s maiden foray into semiconductor production and promises to inject Rs 3,700 crore in investment into the state.

But can this initiative transform Uttar Pradesh into a cornerstone of India’s semiconductor ambitions, and what does it mean for the nation’s quest for technological self-reliance?

A Strategic Leap for Uttar Pradesh

The announcement comes as a significant victory for the Uttar Pradesh government, led by Chief Minister Yogi Adityanath, which has been aggressively positioning the state as a prime destination for high-tech investments.

The HCL-Foxconn plant, designed to produce display driver chips for devices ranging from smartphones and laptops to automobiles and PCs, is expected to process 20,000 wafers per month, yielding an impressive output of 36 million units monthly. This capacity shows the project’s scale and its potential to meet the soaring domestic and global demand for semiconductor components.

Chief Minister Adityanath hailed the decision as a “historic step towards Atmanirbhar Bharat” in a post on X, thanking Prime Minister Modi for the Union Cabinet’s approval. The move aligns with the state’s Uttar Pradesh Semiconductor Policy 2024, unveiled last year, which offers incentives like interest subsidies and stamp duty exemptions to attract semiconductor manufacturers.

The policy has already borne fruit, with the state cabinet approving over Rs 32,000 crore in semiconductor investments on November 4, 2024, including a Rs 28,440 crore proposal by Tarq Semiconductors Private Limited for additional units in the YEIDA area.

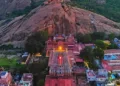

Uttar Pradesh’s Chief Secretary, Manoj Kumar Singh, expressed optimism about the project’s ripple effects, stating, “It’s a great achievement that a company like Foxconn is investing in Uttar Pradesh. We hope Foxconn will invest further in the state.” The strategic choice of Jewar, bolstered by its proximity to the under-construction Noida International Airport and robust infrastructure like expressways and industrial zones, positions the region as an ideal hub for high-tech manufacturing.

A National Milestone in the India Semiconductor Mission

The HCL-Foxconn unit is the latest milestone in the India Semiconductor Mission (ISM), a flagship initiative to establish India as a global player in chipmaking. With five other semiconductor units already in advanced stages of construction—spread across Gujarat, Assam, and other states—the addition of a sixth unit signals India’s accelerating momentum in this critical sector.

These efforts are part of a broader vision articulated by Prime Minister Modi during the inauguration of Semicon India 2024 on September 11, 2024, at India Expo Mart in Greater Noida, where he emphasised India’s potential to become a semiconductor manufacturing hub. The event, attended by representatives from 24 countries, showcased India’s growing clout in the global chipmaking ecosystem.

The five existing projects under the ISM are already laying a strong foundation. In Gujarat, Tata Electronics is constructing a Rs 91,000 crore fabrication facility in Dholera, in partnership with Taiwan’s Powerchip Semiconductor Manufacturing Corporation, aiming to produce 50,000 wafers monthly and create over 20,000 jobs. Micron Technology’s Rs 22,500 crore assembly and testing unit in Sanand, Gujarat, is set to generate 20,000 direct and indirect jobs.

Meanwhile, CG Power’s OSAT plant in the same region, Kaynes Technology’s chip production unit, and Tata Semiconductor Assembly and Test’s Rs 27,000 crore facility in Assam are further bolstering India’s semiconductor capabilities.

The HCL-Foxconn plant adds a new dimension to this ecosystem by focusing on display driver chips, a critical component in consumer electronics, automotive, and industrial applications. Ashok Chandak, president of IESA and SEMI India, described the project as a reflection of “India’s growing maturity in semiconductor manufacturing.”

He emphasised its role in positioning India as a global hub for Outsourced Semiconductor Assembly and Test (OSAT) operations, aligning with the “Make in India, Make for the World” vision.

Why Semiconductors Matter

Semiconductors are the backbone of modern technology, powering everything from smartphones and electric vehicles to defence systems and artificial intelligence. India’s reliance on imported chips, primarily from countries like Taiwan, South Korea, and China, has long been a strategic vulnerability, especially amid global supply chain disruptions and geopolitical tensions. The ISM, backed by strategic policy support and incentives, aims to reduce this dependency while capitalising on rising domestic demand and global supply chain realignments.

The HCL-Foxconn collaboration is particularly significant given the pedigree of its partners. HCL brings decades of expertise in hardware development, while Foxconn, a key supplier to tech giants like Apple and Xiaomi, is renowned for its manufacturing prowess. Their partnership, formalised in January 2024, initially focused on OSAT operations in Bengaluru, but the Jewar unit marks a deeper commitment to India’s semiconductor ambitions. Foxconn’s “build-operate-localise” model is expected to foster local talent and supply chains, amplifying the project’s economic impact.

A Boost for Jobs and Innovation

The HCL-Foxconn plant is set to be a game-changer for Uttar Pradesh’s economy, creating thousands of direct and indirect jobs. Union Minister of State for Electronics and Information Technology Jitin Prasada, representing Pilibhit, lauded the project as a testament to Prime Minister Modi’s vision of making India a semiconductor hub.

“This important unit will create jobs on a large scale,” Prasada said, noting that an electronics hub is also taking shape in the YEIDA area, further enhancing the region’s industrial ecosystem.

Beyond manufacturing, India’s semiconductor journey is being fueled by innovation in chip design. Across the country, 270 academic institutions and 70 startups are developing cutting-edge technologies, with 20 products already taped out by SCL Mohali. Global equipment manufacturers like Applied Materials and Lam Research, along with chemical and gas suppliers such as Merck and Linde, have established a presence in India, signalling confidence in the country’s growth trajectory.

Challenges and Opportunities Ahead

While the HCL-Foxconn unit is a significant step forward, India’s semiconductor ambitions face challenges, including high capital costs, complex technology requirements, and competition from established players like Taiwan and South Korea. However, strategic partnerships, government incentives, and a burgeoning talent pool are helping India overcome these hurdles. The Uttar Pradesh government’s proactive policies, combined with the central government’s ISM, create a conducive environment for sustained growth.

The global context also favours India. With rising tariffs under the Trump administration and increasing demand for semiconductors in sectors like power electronics, defence, and medical devices, India is well-positioned to capture a larger share of the market. The HCL-Foxconn plant, with its focus on display driver chips, taps into this demand, serving both domestic and international markets.

A Vision for the Future

As India’s semiconductor journey gains momentum, the HCL-Foxconn unit in Uttar Pradesh stands as a symbol of the country’s technological and economic aspirations. It reflects a confluence of visionary leadership, strategic partnerships, and robust policy frameworks. For Uttar Pradesh, the project is a chance to shed its image as an agrarian state and emerge as a high-tech powerhouse. For India, it is a step closer to achieving self-reliance in a sector that will define the future.

Comments