The Electronics System Design and Manufacturing (ESDM) sector is no longer a niche segment of technology, it is the very backbone of modern economies. Valued at $4.5 trillion today and expected to soar to $6.1 trillion by 2030, this industry shapes how nations innovate, interact, and build their digital futures. Far beyond chips, sensors, and circuit boards, ESDM defines the way societies work, communicate, and compete in the global marketplace.

India, once a minor player in this arena, has undergone a dramatic transformation. Electronics production in the country touched $115 billion in FY24, nearly quadrupling over the last decade. The momentum is only accelerating, with projections suggesting a fivefold growth in the coming years.

Among the biggest surprises in this story is the state of Uttar Pradesh. Known traditionally for its agricultural dominance, UP has reinvented itself as India’s largest exporter of consumer electronics. Today, it contributes 45 percent of the nation’s smartphone output and 55 percent of mobile component production. Driving this transformation is Greater Noida, which has quietly risen as a vibrant hub for global technology brands.

The policy framework

The seeds of this industrial shift were planted in 2017 when the state government introduced its first Electronics Manufacturing Policy. It was an ambitious step aimed at drawing international investors to a state that had long been overlooked in discussions of industrial modernisation. Within three years, the policy had delivered beyond expectations, investments flowed in, jobs were created, and Uttar Pradesh suddenly featured on the global electronics map.

Riding on this momentum, the Yogi Adityanath-led government unveiled the Electronics Manufacturing Policy 2020. The timing could not have been more strategic. The pandemic had rattled global supply chains, forcing companies to look for reliable alternatives to China. UP seized the moment, widening its policy scope beyond the Delhi-adjacent Noida-Greater Noida region to the entire state. The new plan extended a bouquet of incentives and opened doors for industrial growth in regions like Bundelkhand and Purvanchal, which had historically remained economically stagnant.

Putting UP on the world map

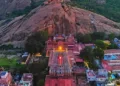

Perhaps the most symbolic moment in UP’s electronics journey came in July 2018, when Samsung inaugurated what was then the world’s largest mobile phone manufacturing facility in Noida. Backed by an investment of Rs 4,825 crore, and sweetened by state incentives worth Rs 250 crore, the project signalled UP’s seriousness about becoming a manufacturing powerhouse. Additional support from the central government’s SPECS scheme, which contributed Rs 460 crore in incentives, further anchored the deal.

For industry watchers, this was not just about one factory, it was a proof of concept. It demonstrated that Uttar Pradesh could provide the scale, policy backing, and cost advantages that global giants were looking for. With rising production costs in China, the Noida plant gave Samsung the edge it needed in competitive global markets, while giving India the credibility of hosting a world-scale facility.

The domestic backbone

If Samsung lent international credibility, Dixon Technologies brought homegrown legitimacy to UP’s industrial ambitions. As India’s largest homegrown electronics contract manufacturer, Dixon has made Uttar Pradesh its base of operations with nine facilities spread across the state. Its subsidiary Padget Electronics established a state-of-the-art smartphone facility in Noida dedicated to Xiaomi India.

With an investment of Rs 256 crore, the unit boasts a production capacity of 25 million smartphones annually and promises 5,000 jobs. This facility reflects not only Dixon’s scale but also the evolving partnership between domestic firms and global tech leaders. Together, such collaborations give UP the diversity and resilience needed to compete on the world stage.

The 2020 policy blueprint

At the heart of UP’s electronics surge is the aggressive incentive package offered under the 2020 policy. The measures are both comprehensive and targeted: interest subsidies of five percent annually for certain units, full exemption on stamp duty, land subsidies of up to 75 percent for anchor investments, and electricity duty waivers lasting up to 20 years. Special support has also been designed for high-tech facilities like semiconductor fabs, effluent treatment plants, and MSMEs adopting plug-and-play models.

Equally important is the geographical spread of incentives. Unlike earlier strategies that concentrated development in the western corridor, the new policy pushes industrial growth eastward. Bundelkhand and Purvanchal enjoy doubled land subsidies and 100 percent power duty exemptions, while regions in central and western UP also benefit from substantial incentives. The approach is not only about creating a global hub but also about ensuring equitable economic growth across the state.

Building the future with EMCs as growth engines

The most tangible expression of this vision is the creation of Electronics Manufacturing Clusters (EMCs). Designed as self-contained ecosystems, these clusters offer common infrastructure, logistics facilities, and innovation support for electronics manufacturers.

EMC 1, spread over 100 acres at YEIDA Sector 10 along the Yamuna Expressway, has already begun attracting big names like Havells.

EMC 2, covering 210 acres in Greater Noida, is poised to anchor the next phase of ESDM growth.

EMC 3, planned for eastern Uttar Pradesh, aims to expand the industrial wave to less-developed regions.

According to IT and Electronics Minister Sunil Kumar Sharma, each cluster has the potential to generate 70,000-80,000 jobs, underlining the employment dividend of the policy.

The next frontier: Closing the import gap

Despite its achievements, India’s electronics industry faces a daunting challenge, overdependence on imports for critical components. In the last year alone, the country imported $70 billion worth of electronic circuit boards. This glaring gap in backwards integration underscores the urgent need to develop the entire value chain domestically.

UP’s policymakers are aware of this gap. Their response includes setting up Centres of Excellence for research, creating ESDM parks to encourage innovation, and bringing MSMEs into the fold through plug-and-play models. The objective is not just to assemble but to innovate, to transform UP into a true ecosystem for electronics.

From agrarian past to digital future

As global companies reconfigure supply chains in a post-pandemic world, India stands as an alternative manufacturing hub. Within India, Uttar Pradesh has emerged as the frontrunner, its success driven by decisive policies, global partnerships, and a clear focus on infrastructure.

The journey from an agrarian economy to a digital manufacturing powerhouse has been nothing short of remarkable. Yet, this is only the beginning. If current trends hold, Uttar Pradesh will not merely participate in India’s digital dreams, it will lead them.

Comments