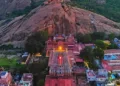

A deep rumble echoed at Sriharikota. Engineers and scientists watched intently as flames burst from the static test stand. The ground was trembling under the force of a 30-tonne propellant monolithic composite motor. This was no ordinary engine; it was the KALAM 1200, the first stage of the Vikram-1 Launch Vehicle developed by Skyroot Aerospace Pvt. Ltd., a Hyderabad-based private space company.

While the event marked a milestone for Bharat’s private space sector, its significance is far beyond the goal of launching satellites. The successful static test also opens a new chapter in Bharat’s missile and defence technology ecosystem with lessons, capabilities and industrial support that will directly influence future missile programmes.

KALAM 1200 and Vikram 1

The first stage, KALAM 1200, named after former President and rocket scientist APJ Abdul Kalam, is a single-piece monolithic composite motor. 11 metres in length and 1.7 metres in diameter, built for high efficiency and reliability. This longest monolithic motor is prepared at the Solid Propellant Plant, Sriharikota. The propulsion technology, manufacturing expertise and testing infrastructure that it employs are similar to those used in strategic missile systems.

Vikram-1 is a three-stage solid-fuelled, small satellite launch vehicle designed by Skyroot Aerospace to place payloads of up to 290 kg into a 500 km Sun-synchronous orbit (SSO). Named after Dr. Vikram Sarabhai, the father of the Bharat space programme, the vehicle is intended to serve the rapidly expanding global market for small satellite launches.

Why this matters for Bharat’s missile future

At its core, the KALAM 1200 motor is a product of advanced solid propulsion engineering, the same technological foundation that is employed in many of Bharat’s missile systems. For decades, missile propulsion in Bharat has been the exclusive part of ISRO and DRDO. The arrival of a private-sector player capable of building such large, precision-engineered composite motors has changed the dynamics entirely.

Solid propulsion requires precision composite manufacturing, propellant casting, thermal insulation and rigorous static testing. By developing a large monolithic motor, Skyroot and other private firms are broadening Bharat’s industrial base for critical propulsion systems. This means future missile programmes will no longer depend solely on state-run production lines; instead, they can draw from a competitive, innovative supply chain. The result is strategic sustainability, a crucial factor in defence preparedness.

Policy shift in making new Bharat

This breakthrough is the direct outcome of the Bharat Space Policy 2023, which opened ISRO’s high-value infrastructure, design expertise and managerial support to private companies.

For decades, Bharat’s private sector served mainly as suppliers of components, never as prime system developers. The 2023 policy changed the scenario by:

Granting Access to private firms for using facilities such as the Solid Propellant Plant at Sriharikota and ISRO’s test stands.

Technical Support by ISRO provides design inputs for key systems to ensure that private projects meet performance and safety standards.

Strategic Integration will help in Bharat’s space economy to $44 billion by 2033, while strengthening national security capabilities.

In the case of the KALAM 1200, ISRO has provided motor design guidance and test stand architecture, while Skyroot executed the manufacturing and integration. This public-private partnership has proven to be a powerful model. The government’s decision to open propulsion development to private firms was driven by

Rising Launch Demand as a large number of small satellites need deployment annually, and ISRO alone cannot meet this demand.

Technology Multiplication will generate more entities, thus mastering composite solid propulsion, resulting in faster innovation for both civilian and military use.

Global Competition has led other nations to leverage private companies for both space launch and missile technologies.

Under Aatmanirbhar Bharat, private production lines reduce dependency on foreign suppliers, which will lead to less failure in supply chains.

Private aerospace firms bring speed, agility and risk-taking ability with large-scale precision. Private entities innovate without bureaucratic delays and also attract private funding for facility expansion and talent acquisition. This will strengthen defence readiness by meeting rapid missile development needs, while enabling DRDO and ISRO to focus on high-end research, system integration and critical innovations. Thus, scalable manufacturing can be generated by private partners.

Beyond Space and Missiles: Making of Vishwaguru

The KALAM 1200 test is a signal to the world that Bharat is building a dual-use propulsion capability with the support of both the public and private sectors. This move will challenge the approach of nations like the US, where companies like SpaceX and Northrop Grumman supply systems for both civilian launches and military programmes. For Bharat, it will help in faster missile upgrades with shorter timelines for next-generation missile systems. The export of Satellite launch services and defence exports will rise.

The static test at Sriharikota is only the first step. The KALAM 1200 will undergo further trials before integration into Vikram-1, preparing for its debut flight soon. This project marks the moment when Bharat’s propulsion capability, both for space and missiles, has truly become a source of pride for the nation. Bharat is moving one step closer to Vishwaguru with the static test of KALAM-1200.

Comments