“Tata-Airbus facility will make India a leading exporter of aircraft, create jobs and boost India’s MSMEs.” Prime Minister Modi at the inauguration of facility on October 28

While there has been talk of Modi 3.0 government, another milestone in Atmanirbhar Bharat has been achieved with the vision of Think Big. In a major landmark event, Prime Minister Modi along with Spanish President Pedro Sanchez inaugurated the ambitious Tata -Airbus facility at Vadodara on 28 October 24, which will manufacture the C-295 transport aircraft for Indian Air Force. This state-of-the-art facility truly marks the beginning of Make in India 3.0 with the aim of making India a major defence manufacturing hub in the world. The last decade has witnessed a steady progression of indigenous defence production during Modi 1.0 and Modi 2.0 government. Under Modi 3.0 government, India is now in a position to take giant strides towards manufacturing world class defence equipment with gold standards of excellence. In that sense, Make in India 3.0 has arrived with well laid out deliverables for domestic consumption and defence exports.

Make in India was launched by Prime Minister Modi in September 2014 with the aim of transforming India into a global manufacturing hub of all commodities and equipment, particularly with the focus on reducing import of costly defence hardware. Prior to 2014, with the exception of few items, India had slipped down as a manufacturing hub and our place was usurped by nations like China, South Korea, Vietnam, Thailand, Philippines, Taiwan to name a few. India was a difficult place to do business by the international players with a plethora of red tape. Under Modi 1.0 government, the focus was on ensuring ‘Ease of doing Business’ and putting system in place. Various ministries and government departments were instructed to cut red tape and display red carpet for foreign investment for manufacturing in India. During this period, the pace of manufacturing obviously was slow and tedious. But a solid foundation could be laid.

During Modi 2.0 government, the manufacturing sector picked up pace and Make in India 2.0 delivered some notable results. This period also saw record Foreign Direct Investment and India emerged as the preferred manufacturing hub over China. China’s reputation took a beating during the COVID-19 pandemic and India was seen by the world as a mature and responsible power with skilled & trained manpower. The conducive business environment boosted job creation and encouraged a new ecosystem of spares and ancillaries under the Micro, Small and Medium Enterprises (MSMEs) in India. In addition, many Start Ups saw good investment by the foreign firms and many of them have already achieved the unicorn status.

The top priority obviously remains self-reliance in defence sector. As part of the larger Atmanirbhar Bharat initiative of the Modi government, the focus is on manufacturing defence weapons, equipment, ammunition and support systems in India. While the Russian military hardware is still more than 60% of our total defence imports, Modi government has given impetus to self-reliance in defence right from the first term in 2014. It is a known fact that the defence industry is dominated by a few nations like the US, Russia, France, UK, China, Israel and these nations charge a premium for any major defence deal. In addition, these nations put strict restrictions and conditions on any transfer of technology. Therefore, the Modi government had to focus on transfer of technology for genuine Make in India as also concentrate on reducing defence imports of many small items which add up to the import bill in dollars. In that sense, military diplomacy has played a key role in such turnaround by major international players like the Airbus Industries.

In October 2021, Ministry of Defence converted Ordnance Factory Board (OFB) into seven 100% Government owned corporate entities. Before this, OFB was largely a sick enterprise with little contribution in manufacturing world class arms, ammunition and equipment. Just in less than three years, the Defence Public Sector Units (DPSUs) are already in profit. Second major reform was to encourage the participation of the private industry. The private companies have significantly contributed towards defence production in the last five years. Indian private companies have manufactured armament and equipment matching global standards and these companies already account for about 25 % of the total defence production, with major chunk going in the exports. Till this financial year 2023-24, the defence exports have crossed Rs 35,000 crores and the export target is likely to touch Rs 50, 000 crores during the current fiscal.

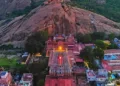

The C-295 transport aircraft is a top-class military aircraft which will be manufactured jointly by the Tata-Airbus facility in Vadodara, Gujrat. This is the first private sector enterprise that would manufacture military aircraft in India. So far, the public sector unit of Hindustan Aeronautics Limited (HAL) has been involved in manufacture of military aircraft in India and had some stellar success in the Tejas project. C-295 is a medium tonnage aircraft which will replace the ageing Avro and AN series of transport aircraft held in the inventory of Indian Air Force. C-295 is a versatile tactical aircraft which is most suitable for operations in the Indian terrain with ability to land on unpaved, grass, highways and sandy/grass airstrips. As per the agreement, 40 aircraft will be manufactured in this facility and 16 aircraft will be delivered directly. Later, this facility would export aircraft. The first C-295 aircraft as Make in India 3.0 project would take to the airs in 2026, indeed a giant step towards a global defence manufacturing hub. Such large-scale manufacturing would serve the purpose when Theatre Commands come up and enhance India’s ability to react to any operational requirements on both the fronts.

It is also significant that the aircraft manufacturing facility would provide direct employment to 3000 personnel. In addition, 10,000 people would get jobs in the ancillary industry that is going to manufacture 18,000 components required for this superior aircraft. Spanish President highlighted a large chunk of youth is undergoing skill upgrade to meet the strict quality control standards during manufacturing. It is unfortunate that our engineering degree curriculum does not give much importance to the needs of the defence industry. The ITIs can become the breeding ground of skilled workforce needed for the expanding defence industry. Besides the DRDO and public sector defence units, the private defence industry should attract the best talent in research, development and production.

Prime Minister Modi stressed on a new work culture of new India where speed in planning and execution of projects is unparalleled. The current facility has come up in exactly two years which was envisioned under the watchful eyes of late Ratan Tata. Aircraft industry is highly competitive and only a handful of countries have the domain expertise. India has entered this elite club but a lot would depend on close monitoring and strict quality control, which are not necessarily Indian strength. Aviation industry is booming in a developing economy like ours and as a nation, our airlines have placed orders for 1200 aircraft. The delivery so many aircraft may take more than five years. Here lies the opportunity for India to become a hub for manufacture of civil aircraft. The value addition can be similar to what Tatas achieved in four-wheeler industry after acquiring Jaguar and Land Rover in 2008.

As we see a more turbulent world, a nation like India has to remain prepared to face multiple security challenges. Make in India 3.0 can be a pathbreaking opportunity for the industry to emerge as the manufacturing hub of new and niche products with a fresh mindset that encourages ideas and innovation. The defence industry has tremendous scope because we as a nation have just realised our potential. With necessary changes in the empowerment model and the work culture, Indian industry, particularly the defence industry is poised for a quantum leap towards unprecedented growth and transformation. Many such cutting-edge products under the Make in India initiative would be needed in our pursuit of Viksit Bharat @2047.

Comments